- April 14, 2023

- Priyam Sakhuja

Are you tired of using off-the-shelf metal components that do not quite meet your business needs? Do you find yourself struggling with quality control issues and unreliable parts that impact your bottom line? If so, you are not alone. Many businesses face similar challenges.

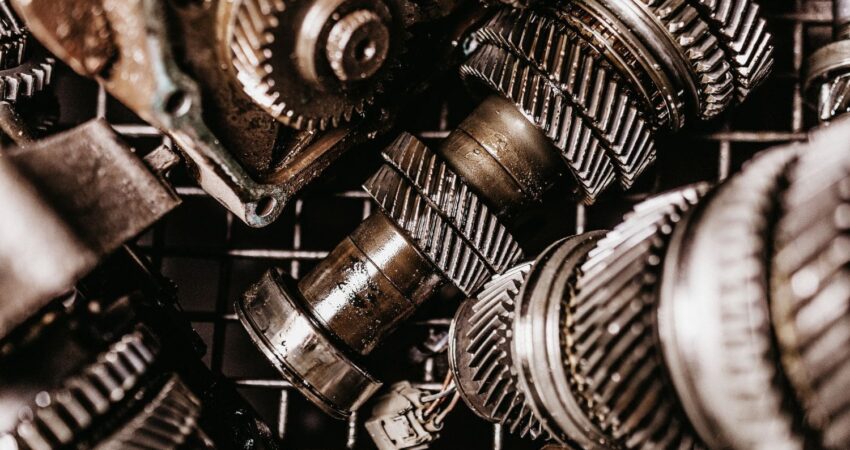

Fortunately, there is a solution: custom metal components manufacturing. It helps businesses in different industries to optimize their manufacturing processes and improve their bottom line.

In this blog post, we will explore the world of custom metal components and highlight the benefits it offers to businesses seeking to stay ahead of the curve. So, don’t wait further and read along the blog to discover how custom metal components manufacturing can be the solution you have been searching for.

Benefits of Custom Metal Components Manufacturing

Unlike traditional mass production methods, custom metal components manufacturing offers multiple benefits, making it an increasingly popular choice for businesses seeking to optimize their manufacturing processes. It not only allows businesses to enjoy great precision but also flexibility and enjoyment.

With that said, here are some of the other advantages that prove why you should use custom metal components manufacturing for your business:

1. Ability to Design Parts to Meet Specific Needs and Requirements

According to a recent study, businesses that use custom metal components experience a 40% reduction in defects compared to those using off-the-shelf components. It is because custom components are designed to fit a particular application and are tested extensively to ensure they meet the required specifications. Moreover, it saves costs as it eliminates the need to modify off-the-shelf components to fit a particular application.

For instance, custom metal components are used in the automotive industry to create specialized parts for high-performance vehicles that require precise tolerances and unique shapes.

2. Use of Advanced Technologies for Precision and Accuracy

Custom metal components manufacturing utilizes advanced manufacturing technologies to create parts with high precision and accuracy. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are used to design and simulate the production of parts, ensuring that the final product meets exact specifications. This technology allows for the creation of parts with tight tolerances and complex geometries that are difficult or impossible to achieve with traditional manufacturing methods.

3. High-Quality Materials for Durability and Reliability

Custom metal components manufacturing uses high-quality materials to create parts that are durable and reliable. Materials such as stainless steel, titanium, and aluminum are commonly used due to their excellent mechanical properties, corrosion resistance, and durability. These materials are often superior to those used in off-the-shelf components, which are often made with lower-quality materials to reduce costs. Using high-quality materials can improve the performance and longevity of parts, particularly in industries such as construction, where parts are subject to extreme conditions and stress.

4. Quick Turnaround Times and Flexibility in Production

Custom metal components manufacturing offers businesses quick turnaround times and flexibility in production. Since custom metal components are designed specifically for a particular application, production can begin as soon as the design is finalized. In addition, the use of advanced manufacturing technologies such as CNC machines allows for high-speed production, reducing lead times and enabling faster product delivery.

Furthermore, custom metal components manufacturing provides businesses with greater flexibility in production. This means that businesses can modify designs quickly and efficiently to meet changing customer requirements or adapt to new market trends. It is particularly important in industries such as automotive and agriculture, where new designs and product innovations are constantly being developed.

5. Reduced Costs Through Optimized Design and Production Processes

Since custom metal components are designed to meet specific needs and requirements, they can often be more efficient and effective than off-the-shelf components. It means that businesses can reduce costs by eliminating unnecessary features or materials, reducing waste, and improving overall product performance.

Furthermore, the use of advanced manufacturing technologies such as additive manufacturing or 3D printing can significantly reduce production costs. These technologies allow for the creation of parts in a single step, reducing the need for costly tooling and setup. In addition, they can produce complex geometries with high precision, reducing the need for secondary operations and further reducing costs.

6. Improved Functionality and Performance Through Customized Solutions

Custom metal components manufacturing offers businesses the ability to enhance their product’s performance and functionality with customized solutions. When a product is designed with off-the-shelf components, it may not perform at its best because the components are not optimized for the product’s specific needs. However, custom metal components can be designed to meet a product’s exact specifications, resulting in enhanced performance and functionality.

For example, in the automotive industry, custom metal components can be used to optimize the aerodynamics of a vehicle, resulting in improved fuel efficiency and reduced emissions. In the agriculture industry, custom metal components can be used to improve the efficiency and precision of equipment, resulting in better crop yields and reduced waste.

7. Enhanced Product Aesthetics and Branding Opportunities

With custom metal components, businesses can choose from a wide range of materials, finishes, and designs to create a unique and distinctive look for their product. It can help businesses differentiate themselves from their competitors and create a strong brand identity.

For example, in the automobile industry, custom metal components can be used to create unique, high-end finishes that enhance the vehicle’s overall aesthetics and appeal to customers. In the oil and power industry, custom metal components can be used to create branded equipment that reflects a company’s values and mission.

Conclusion

Custom metal components manufacturing offers numerous benefits to businesses in various industries, from precision and accuracy to high-quality materials and reduced costs.

When you consider custom metal components manufacturing, it is crucial to partner with a trusted and experienced manufacturer. A reputable manufacturer can help businesses navigate the process, ensuring that their specific needs and requirements are met and that the final product is of the highest quality.

If you are interested in exploring custom metal components manufacturing for your specific needs, we encourage you to consider Catalyst Manufacturing Pvt. Ltd. By partnering with us, you can unlock the full potential of custom metal components manufacturing and gain a competitive edge in your industry.